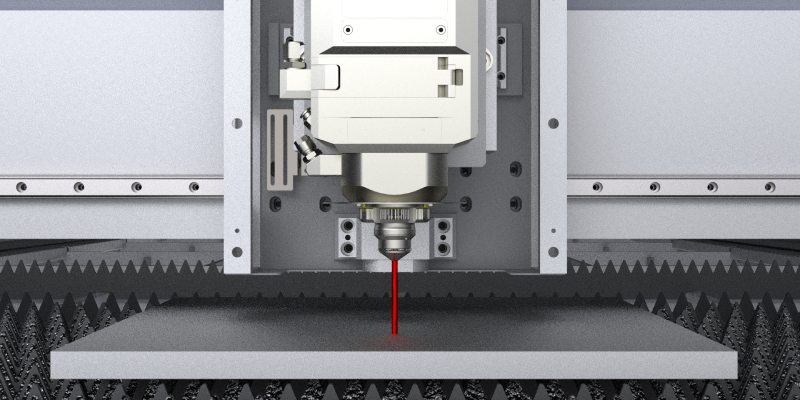

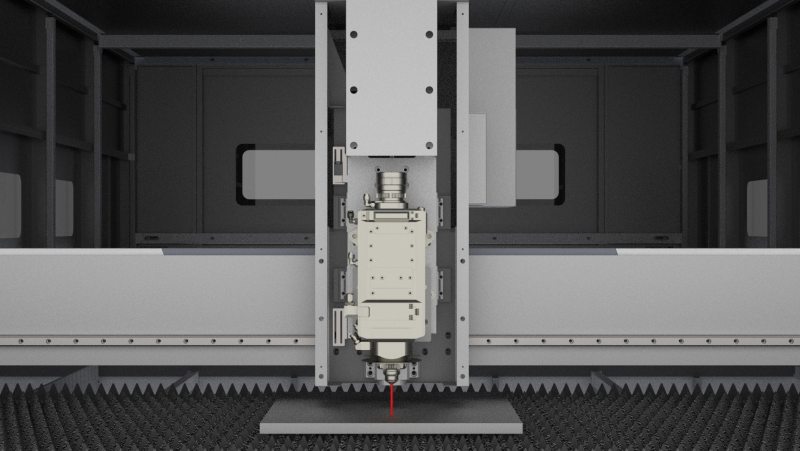

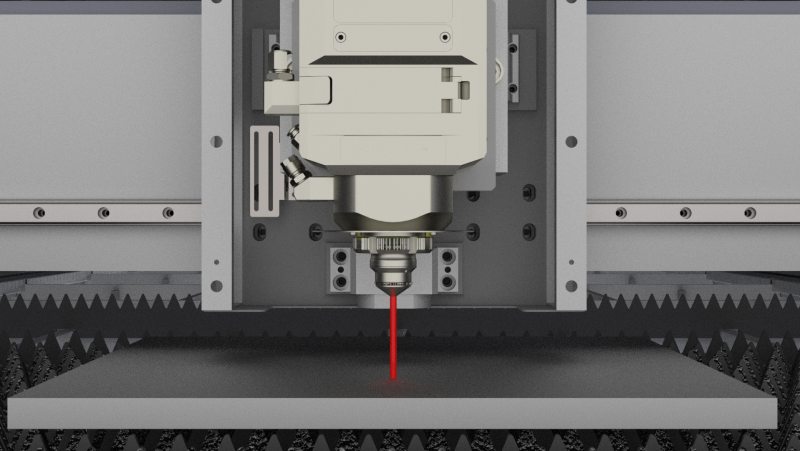

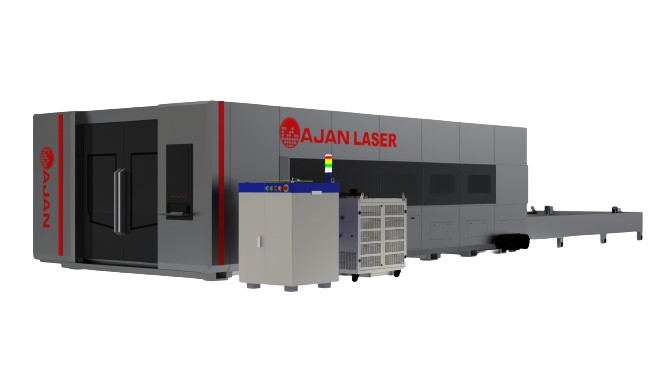

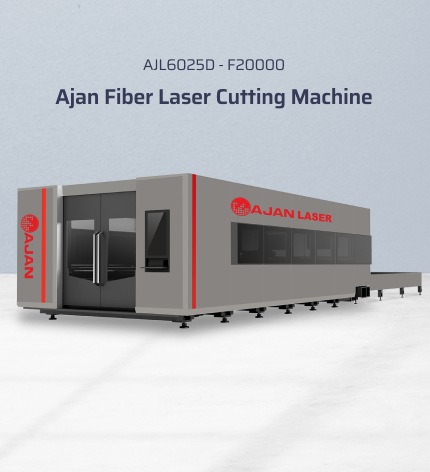

Discover fast, flexible and precise smart machines for laser cutting!

Our company, which carries the innovative spirit of Izmir, aims to revolutionize metal processing technology with more than a half century of experience. We redefine industry standards with the high-tech products we develop. We as Ajan Elektronik are opening a new era in cutting with high precision, speed and efficiency.

Ajan Fiber Laser Cutting Machine Technical Specifications

Performance Parameters

Application Areas of Ajan Fiber Laser Cutting Machine

After Sales Service

The warranty period of the laser cutting machine is 2 years against production and manufacturing defects. During the warranty period, replacement parts due to malfunction will be provided free of charge.

Dust contamination inside the cutting head, optical cables, QBH output heads, laser, consumables (such as optical lenses, cutting nozzles, etc.) and accidents due to condensation or internal icing are not covered under warranty.